ULTRA-LOW-COST INDUSTRIAL HYDROGEN ON-SITE

The "Over-the-Fence" Solution for Immediate Heavy Industry Decarbonization

Gas

pipeline

The

reactor is connected to the nearest gas pipeline network.

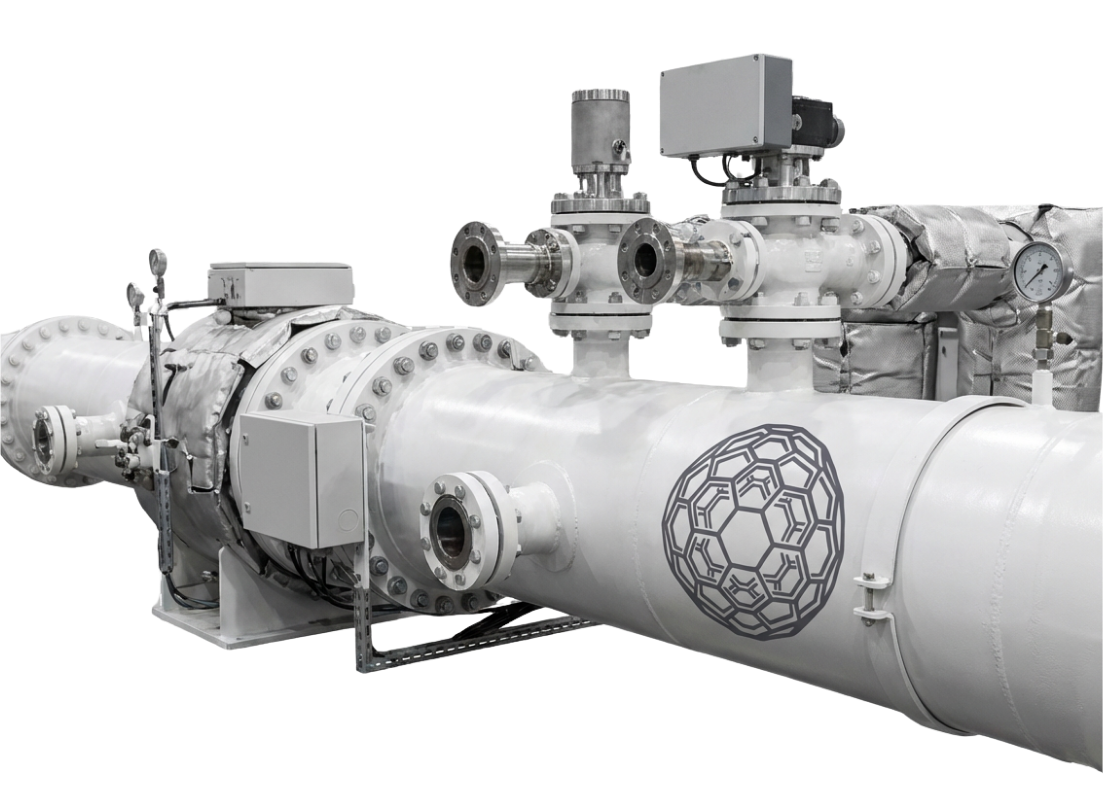

Pyrolysis Reactor

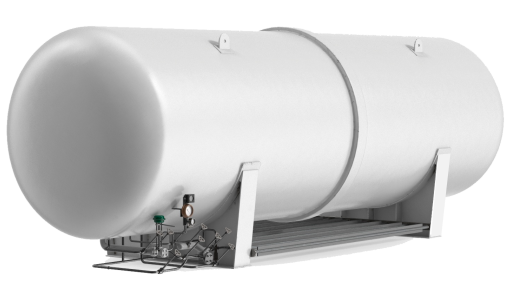

Solid carbon storage tank

Low pressure hydrogen storage tank

High-volume Centrifugal or Reciprocating Industrial DRI Supply

Industrial Pipeline / DRI Injection Ports

Why M2SC is the Global Industrial Choice

Integrity Farm Technologies (IFT) provides a revolutionary on-site hydrogen (H2) production model designed specifically for heavy industrial processes. Our M2SC technology utilizes adiabatic pyrolysis to extract ultra-pure H2 directly at the point of use.

Lowest Market Costs

Production costs 3-4x lower than current market solutions like electrolysis.

Carbon-Negative

Sequesters carbon in a permanent physical state instead of releasing CO2.

Massive Scalability

Engineered for high-volume, continuous supply from reactor to injection.

Seamless Integration

Supply stations optimized for industrial pressure requirements (10–30 bar).

Technical Infrastructure Flow

A dedicated on-site utility suited for Direct Reduced Iron (DRI) steel plants, chemical refining, and high-temperature thermal energy.

M2SC Pyrolysis Reactor

Splits methane feedstock into hydrogen and solid carbon via proprietary R&D technology.

Low-Pressure Buffer

Ensures a constant and stable reservoir of H2 for 24/7 industrial operations.

Industrial Compressor

High-volume units match the specific injection pressures required by your facility.

Process Injection

Direct pipeline delivery into industrial furnaces or chemical reactors.